New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 Re: Science, Technology, and Astronomy » Solar Observations Pure Science at Work » Yesterday 21:42:40

tahanson43206,

I want to know how close we are to answering questions about the magnetic reconnection observations that NASA and the US Air Force spent so much money on.

New theory explains mystery behind fast magnetic reconnection

Here's a page where you can get access to the data being collected:

MMS Science Data Center

#2 Re: Human missions » NASA may alter Artemis III to have no Starship landings. » Yesterday 21:23:08

If I was an astronaut, I'd be mortified that the Orion capsule has been in development for over a decade at this point, but they still don't know why the heat shield is not behaving as it should. Given that Avcoat is a legacy technology with thoroughly proven flight heritage behind it, that strikes me as wrong on multiple levels. Tinkering with a known working design that's done its job every single time, merely to save a buck or two, is unforgivable. Avcoat wasn't designed to be cheap, it was designed to withstand a screaming reentry. If you're that concerned about cost, then you'd never fly to space to begin with, let alone go to the moon. Whoever made that decision should be flown on the first crewed mission, whether they have astronaut training or not. Let's see how fast they make the correct design decisions when it's their rear end that gets BBQ'd.

I wonder how much time and money has been lost trying to save money while doing something that will never be cheap or easy.

#3 Re: Science, Technology, and Astronomy » Planting Ships in the Ground » Yesterday 13:08:10

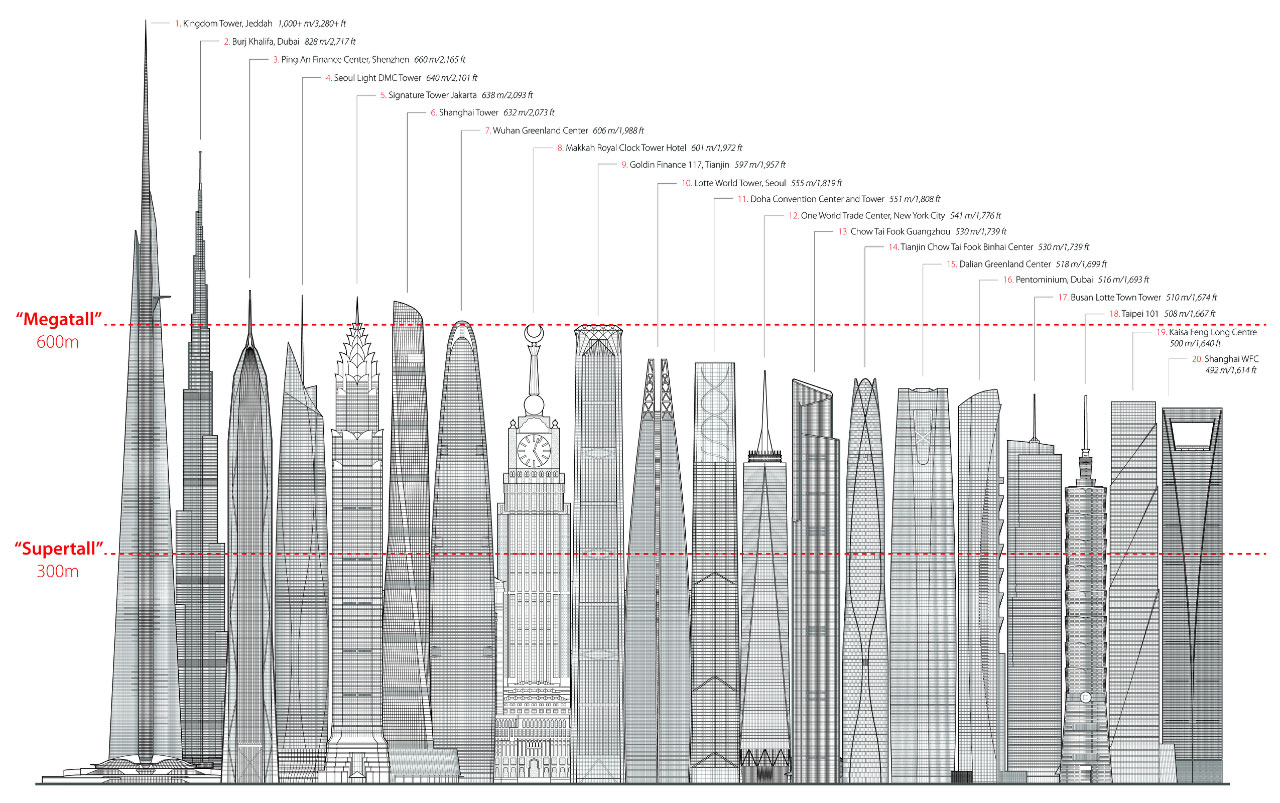

Ping An Finance Center, Seoul Light DMC Tower, Shanghai Tower, Wuhan Greenland Center, Lotte World Tower, Doha Convention Center, Tianjin Chow Tai Fook Binhai Center, Pentominium, and Shanghai WFC... All of those "buildings" are astonishingly good facsimiles of sleek ship hull designs that some architects thought would be a good idea to plant into the ground near the ocean, stern-first. They're all set into massive steel-reinforced concrete foundations. Why that seemed like a "good idea" when ships could be built instead, for far less money and material input, who knows? Those buildings all took multiple years to construct, as doctoral candidate Lu Ping pointed out, and they all cost a lot more than palatially well-appointed luxury cruise liners, which are now "home" to thousands of people. I would settle for a spartan but clean and well-equipped "seat at the table" for everyone, aboard ships so large and strong that they can only be sunk by deliberate human action.

Even the rather modest accommodations afforded to US Navy ships are far better able to sustain life than any palace of antiquity, they can and do travel millions of miles during their operational lives, and they're better protected than Fort Knox. The US Navy threw ordnance at one of their old super carriers for a couple of weeks before accepting that deliberate scuttling was the only way she'd go under. Megaton class nuclear weapons detonated within a few hundred yards didn't sink WWII escort carriers and battleships. Against a ship the size of a skyscraper, you'd have to detonate a nuclear weapon inside the ship to sink it. The larger the ship, the greater its internal compartmentalization, thus the more it takes to sink it. To sink a super carrier, you need to flood about 70% of the compartments below the water line. When all the hatches are battened down below the water line, that's not simple or easy to do. Against a skyscraper-sized ship with sufficient internal compartmentalization, that's functionally impossible without deliberate action. Titanic was a tinker toy compared to a "skyscraper ship", and she had no effective compartmentalization below her water line, in order to "save money". Design really does matter. Titanic was also built with rivets rather than welds. Tearing steel apart is not as easy as fracturing a rivet. There's no such thing as an "unsinkable ship", but there is such as thing as "cannot readily be sunk without deliberate acts carried out by those aboard to do so". Both super carriers and properly designed skyscraper ships both fall into this category.

As Lu Ping noted, steel is efficient, because steel is strong. Modern steels can be very strong- stronger than any alloy of Aluminum or Titanium by a lot, and Titanium suffers worse fatigue life than high strength steel when you make the Titanium alloy strong and hard. The leaps and bounds improvement of a bewildering variety of steel is the only real story. All the would-be "super alloys" are specialty products that don't see much use because there's not much they can do better than steel. There are no 350ksi Aluminum or Titanium alloys in existence, so far as I'm aware. In contrast, there are multiple different families of ultra high strength steels with different properties. Now that we have welding techniques and materials to use that are as strong and hard as the base metal, but no weaker or stronger or softer or harder, which is critically important to weld joint durability, we now possess the ability to make very strong and very light mega structures that resist both corrosion and deformation under load.

The right kind of steel doesn't appreciably corrode over 25 years. Nippon Steel NSGP-1 / NSGP-2:

Nippon Steel - NSGP-1 and NSGP-2 Corrosion Resistant Steels

Ultra-pure Iron from these new "green steel" projects, which always fail to consume less energy than traditional manufacturing methods, because energy input associated with reducing entropy is a "real concept" that is never going away, yet generally do succeed in producing measurably better end products, we have the materials we require to build with, and it happens to be the one structural metal we produce and consume more of, by a significant margin. Extreme purity Iron also implies slower corrosion, because oxidation of the microstructures (grain boundary reinforcements from alloying elements provide) that permit below-surface level corrosion to begin are dramatically reduced. Use of other metals like Lithium, Copper, Aluminum, and Titanium grab headlines, but steel continues to do the real work of building out a modern society.

#4 Science, Technology, and Astronomy » Planting Ships in the Ground » Yesterday 03:43:11

- kbd512

- Replies: 4

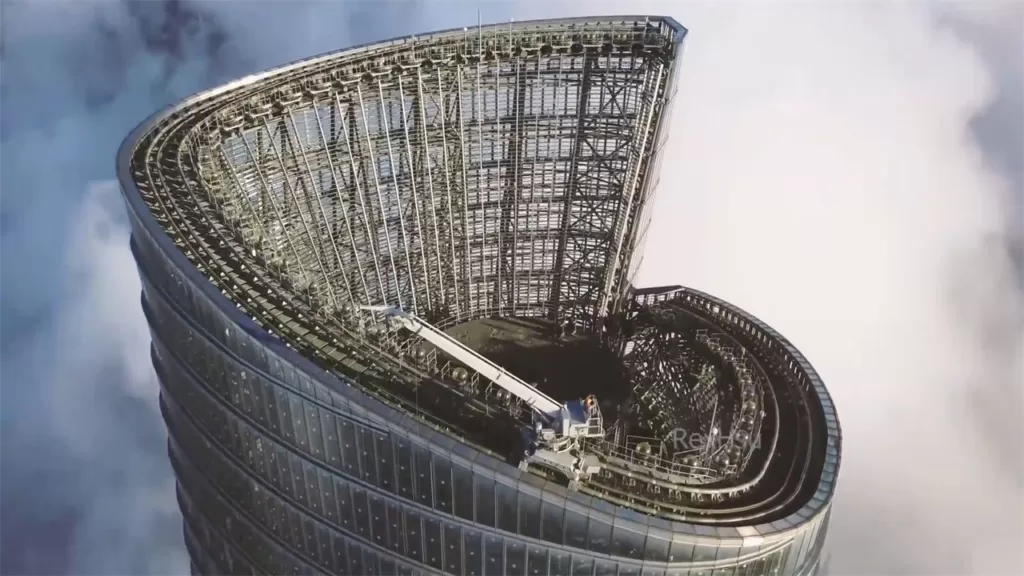

It occurs to me, looking at the designs of our most modern skyscrapers, that we're spending a lot of time, money, and energy planting what would otherwise be perfectly good ship hulls, in bedrock, where they can never go anywhere. Earth is quite literally covered with water, but to demonstrate our engineering prowess, we've fixated on building up instead of building out.

With the amount of time, money, and energy we've expended on glass and steel reinforced concrete, we could've flipped those boat hulls 90 degrees, built them from solid steel, and put them in the water where they belong. Ships at sea, the size of skyscrapers, don't have much to fear from the weather, or rising ocean levels, because they float. We're never going to run out of space to put them. We need slipways to launch them from and machines to build them quickly and with minimal labor, but welding them much closer to the ground in drydock has to be easier than this:

Concrete has low embodied energy compared to steel, but we're using enormous quantities of it, and recycling it is not so easy. Glass has more than double the embodied energy of steel and the sheets of this stuff on skyscrapers are as thick as the hull plating on many modern large ships. Globally, glass production is about 3X that of Aluminum production. Steel production is about 9X that of glass. Concrete production is about 16X that of steel production.

In the end, no energy is being saved. We're playing a silly shell game with silly results. None of this is intended to suggest that glass, concrete, and Aluminum aren't very useful, because they are, but we're only fooling ourselves if we think whatever we're presently doing is "saving" something. It's not.

People require sturdy structures to live in, they must have basic needs met, and they need jobs that provide a sense of accomplishment. A ship checks off most of those boxes. We still need farms, at least until we figure out how to synthesize food from scratch, but ships are great places to both transport and store people, food, fuel, and manufactured goods.

Why is it cheaper to build a luxurious cruise ship than a building? - Lu Ding - PhD Candidate

One of the newest cruise vessels, the MSC Bellissima cost £1 billion for its 450,000 sqm deck area spreading over 19 decks, which makes its construction cost £2200 (€2400) per square meter. This amount looks enormous, nevertheless, it includes its propulsion system, control and navigation systems, a grand atrium, 2 theatres, 12 restaurants, 4 swimming pools, a water park and all the interior decoration. To make the comparison, to my best knowledge, a new mixed-use project in Amsterdam may cost €2200-2800 per square meter to build, which becomes even more if high-rise construction is involved. This does not yet include the interior fit-out, costing another €500-1000 euros extra per square meter. This made me wonder, why are buildings we design nowadays so expensive to build? And why ship building, on the contrary, could have a lower price tag. In this article, I made a bold assumption of a few possible reasons to this:

#5 Re: Science, Technology, and Astronomy » Trough Solar Collector- Design- Construction- Operation- Maintenance » 2024-04-29 14:15:18

Most elemental Sulfur production in America / China / Russia / Saudi Arabia / elsewhere comes from refining oil and natural gas. That is another way in which hydrocarbon fuels serve multiple purposes.

Domestic elemental Sulfur production was 8,706,000,000kg in 2019, according to USGS 2021 data.

8,706,000,000kg / 1,840kg per cubic meter = 4,731,522m^3

That means we need more than 2 years of domestic Sulfur production to power California, a state that only consumes 7% of the total energy of the US. I wish someone else besides myself or Calliban could begin to appreciate the enormous scale of the task of replacing hydrocarbon fuels, and stop pretending that some new photovoltaic or battery invention will come along to solve a problem that is entirely about production of the materials and machines required to do the work.

"Knowing" how much of what materials are required is only basic math and accounting skills. If you don't like the numbers, then you need to come up with a new invention. We've been working on electrochemical battery technology for more than 100 years. We have Lead-acid, Nickel-Cadmium, Nickel Metal Hydride, Lithium-ion, and Sodium-ion. Every rechargeable battery cell chemistry is some minor variation thereof, but none of them remotely approach the energy density of chemical oxidation reactions involving Carbon, Hydrogen, and Sulfur.

Are electrochemical batteries great bits of tech?

Sure they are. For powering your cell phone, wristwatch, or laptop, they absolutely are. In spite of how great they are for small portable electronic devices or cordless power tools, all of them are exceptionally poor at powering anything significantly larger and more powerful than that. Despite all the ridiculous stunts which have attempted to make "Lead airplanes" fly, nobody with more uncommon sense than money is buying airplanes made from Lead. The reason is not a big oil company conspiracy to prevent us from ushering in the new era of Lead airplanes. Devices which need to be reasonably light and compact, such as all motorized transport vehicles that move at highway speeds or faster, in order to make them most useful for the widest possible range of uses, are no longer light and compact when batteries are used. That is the real ideology-free reason that engineers pursued combustion engines over batteries for powering vehicles. Engineers don't really care if you want them to engineer something ridiculous, either. They'll happily take your money. Fools and their money are easily separated from each other, and if you can do it legally, the fool will be none the wiser, but much poorer, so even within a litigious society such as America, being foolish with money still has real consequences.

US EPA - Sulfur Supply Chain - Executive Summary

Applications: waste water treatment, Sulfuric acid production, fertilizers and pesticides production, chemicals production.

#6 Re: Science, Technology, and Astronomy » Trough Solar Collector- Design- Construction- Operation- Maintenance » 2024-04-29 12:56:31

4 Materials to Consider for Heat Transfer Applications Involving Sulfuric Acid

Umax Advanced Ceramic - Silicon Carbide Cermaic Heat Exchangers

Sulfuric Acid Concentration Plant

A Laboratory-Scale Sulfuric Acid Decomposition Apparatus for Use in Hydrogen Production Cycles

As part of the US DOE Nuclear Hydrogen Initiative, Sandia National Laboratories is developing the high temperature process for conversion of sulfuric acid to produce sulfur dioxide as part of the thermochemical Sulfur-Iodine (S-I) cycle that produces hydrogen from water. The Sandia process will be integrated with other sections of the S-I cycle in the near future to complete a demonstration-scale S-I process. In the Sandia process, sulfuric acid is concentrated by vacuum distillation and then catalytically decomposed at high temperature (850°C) to produce sulfur dioxide, oxygen and water. Major problems in the process, corrosion and failure of high-temperature connections of process equipment, have been virtually eliminated through the development of an integrated acid decomposer constructed of silicon carbide and quartz. The unit integrates acid boiling, superheating and decomposition into a single unit operation and provides for exceptional heat recuperation. The design of acid decomposition process, the new acid decomposer, other process units and materials of construction for the process are described and discussed.

2006 DOE Hydrogen Program Review - Sulfur-Iodine Thermochemical Cycle

Did anybody else catch the power density of the chemical reactor core?

It's 75MW/m^3.

The AP-1000 nuclear reactor design is 109.7MW/m^3.

That means the power density of the Sulfuric acid chemical reactor pressure vessel approaches that of an advanced nuclear reactor design.

If we can't make that work, then 700Wh/L / 0.7MWh/m^3 Lithium-ion battery energy density is far too poor to even bother with.

Sulfuric acid is 1,840kg/m^3 at room temperature, so our chemical reactant stores 23,000MJ/m^3 (12.5MJ/kg * 1,840kg/m^3) or 6.389MWh of thermal power per cubic meter of reactant volume. Even if we're only 50% efficient at turning that thermal power into electricity, that's still 4.5X better than the latest and greatest Lithium-ion batteries. Battery manufacturers would give up almost any amount of money for a 4.5X volumetric energy density improvement. The batteries could get even heavier but EV manufacturers wouldn't care if you could simply get rid of the ridiculously high volume occupied by all types of electrochemical batteries, in comparison to gasoline. The volume consumed by a battery is its own form of inefficiency, due to all the packaging materials required to enclose the battery, as most of the battery pack is not active material, it's packaging materials.

36,300,000,000,000Wh / 3,194,500Wh/m^3 (50% thermal efficiency) = 11,363,281m^3

36,300,000,000,000Wh / 700,000Wh/m^3 (Lithium-ion batteries) = 51,857,143m^3

Sulfuric acid is the most widely produced bulk chemical across the globe with a yearly output of around 201.6 million tons.Mar 24, 2023.

201,600,000,000kg per year / 1,840kg = 109,565,217m^3

California only represents about 7.18% of the total annual US electric energy consumption, but they need about 9.64% of the total annual Sulfuric acid supply to achieve 100% "green energy" consumption, according to them.

Total global Lithium production was 180,000t in 2023, as opposed to 201,600,000t of Sulfuric acid.

Are we going to scale that up multiple orders of magnitude to meet demand?

Obviously not.

Why, then, is everybody acting as if we are, when anyone who can count knows that is not going to happen in the next 20 years?

The process of opening a new mine is about as fast as the process of approving and building a new nuclear reactor.

Alternatively, we're going to create a miracle battery with 5X greater energy density, so that Lithium production doesn't falter and the battery can store as much energy as a reversible oxidation reaction. We're going to invent some brand new electrochemical battery tech to supply the energy required, because otherwise there's not enough metal production to implement the solution. We also make 100,000t of Sodium metal, annually. I'm not so sure that's gonna scale up quickly, either, and because energy density is lower than Lithium, of course we'll need evern more metal to work with.

#7 Re: Science, Technology, and Astronomy » Trough Solar Collector- Design- Construction- Operation- Maintenance » 2024-04-29 04:10:02

Doing some simple math on what seasonal battery energy storage will cost the state of California, not the entire US, they think they need 36,300,000 MWh worth of battery energy storage to deal with seasonal demand fluctuations. Over-building photovoltaics just means more land use and environmental destruction, more embodied energy, lower EROEI, and even higher prices paid by consumers, plus more burning of hydrocarbon fuels.

The 3,000MWh Tesla Lithium-ion battery cost built at Vistra Moss Landing cost $560M.

The State of California thinks needs 36.3 million MWh worth of Tesla's battery storage to deal with photovoltaic power fluctuation by both seasonal and diurnal cycles:

$0.18666/Wh * 36,300,000,000,000Wh of energy storage = $6,776,000,000,000

Think about where the price has to go, to best $0.18666 per Watt-hour of electrical energy storage. Can it drop to zero? It pretty much has to, or photovoltaics are not going to provide 70% of the energy, now or ever.

$6,776,000,000,000 / $850,000,000,000 (FY2024 US military budget) = 7.97 years of America's FY2024 military budget

In 10 years when the Tesla battery croaks, we'll need another $6.776 trillion dollars to replace it

If you can't see why we're never going to do this "electronic-everything" insanity, it's because you're a magical thinker, so no amount of explaining will help you understand.

Crescent Dunes sold power at $0.135/kWh, and included 10 hours of storage, which means it stored enough power to actually produce it's nameplate capacity 91.4% of the time, which was also built for the State of California.

If Crescent Dunes was "too expensive" or "not profitable", then nothing involving sufficient electrochemical battery energy storage will fit that description for many decades to come.

What happened with Crescent Dunes?

The failures at the plant had zero to do with the plant not working, and almost everything to do with the people building the plant not following the instructions of Aerojet-Rocketdyne, the people who designed the plant, who did actually know what they were doing.

What was the moral of the story?

Never accept a pennywise pound foolish design or operating concept.

What are photovoltaics and electrochemical batteries?

A pennywise pound foolish design concept that is never going to scale-up to the degree required, unless electrochemical batteries become 6X cheaper than they already are. Since 70% to 80% of the cost of all photovoltaics and electrochemical batteries is now the raw materials used, that's a really good indicator that such a thing is highly unlikely to ever happen- unless the prices of photovoltaics and battery making materials alone continues to fall while all other prices increase. Over the past 5 years, we've seen the opposite happen. All prices have increased, to include the price of Lithium, Copper, and Silicon, because that's how market economics works when demand grossly exceeds supply.

The batteries will be replaced 2.5X during the life of the photovoltaics and the photovoltaics will be replaced 3X as often as a solar thermal power plant. All of that costs money. The costs won't be "miracled away" by ridiculous beliefs about things only continuing to get cheaper into perpetuity. That clearly isn't happening right now, and the assertions that they will happen in the future require that costs only run in one direction over time. Scarcity and depletion ensure that won't happen.

A solar sulphur cycle to make unlimited thermal energy storage

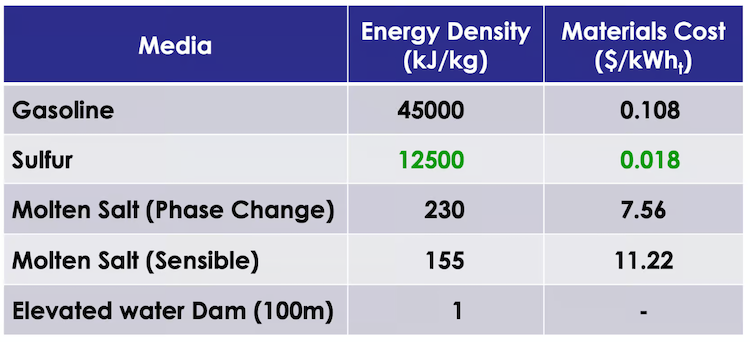

Are Lithium-ion batteries ever going to cost $0.018/kg, while storing 12.5MJ/kg?

Current Lithium-ion batteries store perhaps 1MJ/kg when they're brand new. Either a miracle is going to happen to increase battery energy density by 10X, as well as cycle life and durability, or far more likely, no such thing will happen during our lifetimes, so we're stuck with a pennywise pound foolish "solution" that solves nothing at the scale of the problem of attempting to replace hydrocarbon fuels.

tahanson43206 asked for more info about the costs of solar thermal power during our last weekly meeting, so here's some of that:

Profitability and break-even points, ROI with CSP alone and TES, spinning reserve capacity credits, etc (from 2010):

The Value of Concentrating Solar Power and Thermal Energy Storage

The part I like is that a backcasting statistical model for CSP can predict profitability with 87% accuracy / fidelity to actual. They said that TES cannot be justified on economics alone, but neither can photovoltaics with batteries. That said, if you want a 70% wind and solar powered electric grid, then that can only be done profitably using a dirt-cheap energy storage medium. No kind of electrochemical battery is anywhere close to the price of dirt, unlike Sulfur, which is $18 per 1,000kg, and it stores 12.5X more energy than any kind of battery, and it can be recycled endlessly, and it can be stored outside on the ground like dirt or coal, and it never "loses capacity" as it ages (because Sulfur is Sulfur forever), and it requires no additional mining activities to provide a supply sufficient to meet global energy storage requirements. The "pit of crushed rock" idea from MIT is even cheaper, at $2 to $4 per kWh.

Much like fusion, cheap / reliable / long-lasting electrochemical batteries are only 5 to 10 years away. Just like fusion, they always will be.

#8 Re: Interplanetary transportation » Large scale colonization ship » 2024-04-24 12:23:23

If the large ship will be made from steel, which to my knowledge is completely unaffected by UV light, then how about using UV-C laser equipped robots set to "kill mode" after all the humans leave the room?

Given minimal furnishings, a robot could cover every square inch of a room to keep the nasties at bay. We could do the same thing with ventilation ducting to tamp down on mold. A small robot crawls around in the ventilation ducts and blasts the surfaces clean with UV-C lasers. We'd have UV-C lasers permanently mounted to evap coils so that the humidity doesn't breed mold and bacteria.

#9 Re: Science, Technology, and Astronomy » Materials Mechanical Properties Terminology » 2024-04-24 11:39:20

Much like ceramic matrix composites (CMCs), and ceramic metal matrix composites (CMMCs), high entropy alloys (HEAs) like the Nb45Ta25Ti15Hf15 alloy investigated in the article that tahanson43206 provided a link to, are the next generation of metal alloys for extreme high and low temperature performance.

The CMCs and CMMCs are either heat shielding materials for hypersonic vehicles or extreme temperature components within the hot sections of jet and rocket engines, especially combustor cans, afterburner components, convergent-divergent nozzle components, and uncooled rocket engine nozzle extensions. CMCs and CMMCs exhibit extreme resistance to oxidation at high temperatures. HEAs are interesting for sCO2 turbines and RamGen engines (supersonic inlet velocity gas turbines for Mach 2 to Mach 3 operation), as well as the cooled portions of rocket engine nozzles, turbopump components, main injector plates, injector pintles, hot section expansion turbine blades, engine casings, and fasteners in jet engines, etc. The nozzles and combustor cans don't require extreme tensile strength, but they do require extreme thermal shock and oxidation resistance.

Initial testing of the aforementioned HEA indicates good creep strength, which is mandatory for sCO2 gas turbine components operating at both high temperature and pressure, but I want to see the results of other basic tests such as oxidation resistance, stress-corrosion cracking, resistance to chemical attacks, etc. There are a myriad of different test results we require before judging these novel materials as suitable for aerospace applications. The issues associated with the use of D6AC high strength steel in the F-111 wing boxes and fuselage immediately comes to mind about what can happen if you assume too much and know too little. There was nothing intrinsically wrong with using D6AC, but forging, heat treatment, and corrosion control all mattered greatly, but were little understood and little appreciated until they became real problems during both manufacture and long-term service.

Calliban already indicated what can go wrong with high strength steels. I have no way of knowing how well made his rapier was, but heat treatment is critical to high strength steels. The stronger and therefore harder the steel, the lower its impact resistance. A rapier's blade is subjected to repeated sharp impacts over a very small surface area, analogous to a lifetime of impact strength tests, so perhaps not the best application for a very hard steel. 1095 and other low alloy plain carbon steels, with appropriate heat treatments, are more typical for such blades. Steels like 1095 and 5160 are not as hard or strong, but much tougher and more ductile. This is why Mangalloy found use in forging hammers, rock crushers, and tank tracks. More recently, with the development of appropriate welding techniques, Mangalloy is now used for LNG transport and storage, because it remains tough and ductile at very low temperatures. While aircraft landing gear are a well known application of maraging steels, and also subjected to repeated extreme force impacts, those impacts occur over much larger bearing surface areas, oleos increase the length of time over which load transfer occurs upon landing, and extreme process control is applied to every aspect of their manufacture and maintenance. Knicking or cutting ("notching") high strength / high hardness steels can and does lead to fractures. Titanium alloy parts like landing gear legs or oleos and aircraft shear bolts common for engine mounting in high performance jet aircraft, behave in a similar manner when knicked or "notched".

Every so often someone within the homebuilt aircraft community has the bright idea of using Titanium alloy to reduce the weight of engine mounts, bolts, and the firewall. The smart ones who listen to others are advised against it, not because it won't work, as it absolutely will work if all the welding and handling precautions not to knick the metal anywhere are followed correctly, but mistakes do happen. The simple reason is that 4130 chrome-moly tubing is so thoroughly proven to work, even when the welding or handling of the components are less than perfect. Messing up 4130 takes real effort, even though it can be done. Other countries require that the welder be aerospace certified to weld an engine mount or gear leg. That's why you see so few tube and fabric aircraft in other countries, but lots of them in America. Here in America, we don't have any such requirement for welding. Since 4130 is the most frequently used material, even homebuilders with limited experience encounter very few weld failures where amateur welders are involved. Most have the good sense to practice their technique, try to break the weld, and to seek out advice for how to do it properly. Welding takes a few weeks to learn to do well. Riveting takes a day or two, which is why American WWII aircraft were mostly riveted Aluminum. Welding difficulties aside, the people who make the Titanium Cessna landing gear will tell you that any scratches or knicks to the gear legs must be buffed out. Their product is primarily intended to reduce the weight of the gear for bush planes, to partially compensate for the heavier tires and brakes. That's all perfectly logical, but the propellers for bush planes frequently throw small rocks when landing in river beds, some of which will inevitably strike the gear legs, amongst other parts of the airframe. A pair of Cessna main gear legs cost $2K to $5K. Titanium costs over $30K. That's quite a lot of money to drop 50lbs or so over steel. The weight savings of Titanium over 4130 are real and meaningful, but so are the increased manufacturing costs and maintenance requirements to avoid landing gear fractures in a place you may not easily get out of, such as the Alaskan backcountry.

When the Navy switched from HY-80 to HY-100 / HY-110 / HY-120 for submarine hulls and now the Ford class aircraft carrier hulls, the corollary was increased welding costs, increased weld rejection or failure rates, and increased inspection an maintenance requirements. The stronger steel was used in the more modern Sea Wolf and Virginia classes to increase dive depth. The Ford class uses the stronger steel to avoid significant weight increases related to its much larger flight deck area and heavy EMALS catapult equipment. HY-110 allows the Ford class to retain the same basic super carrier hull design as the Forrestal / Kitty Hawk / Enterprise / Nimitz classes. All of the super carrier hulls, from Forrestal to Ford, are based upon the Forrestal class hull design, with minor increases to beam width to accommodate increasingly greater weight of installed equipment / fuel / aircraft. The Ford class is "maxing out" the Forrestal class hull design. Any further weight increase would require a hull redesign. HY-100 / 110 / 120 avoided the need to do that. Forrestal class ships started at 80,000t at full load, Kitty Hawk and JFK were heavier, Enterprise significantly heavier, Nimitz modestly heavier than Enterprise due to reactor improvements, whereas the new Ford class is now at about 110,000t with a full load. Any "heavier-than-Ford" super carrier design would require a lengthened hull with an internal redesign for weight and balance purposes as well as that all-important optimal hull form to attain 30 knots for launching jet aircraft. The Forrestal class was the fastest of all the super carrier designs- faster than all the nuclear powered carriers. Internet folklore aside, every super carrier since Forrestal has increased beam and draft, but the same installed geared steam turbine engine power, which means they've become progressively slower, with the Ford class being the slowest of all the super carriers. Ford is the slowest because it has to shove more water out of the way as the beam width crept up. You'll notice that the later Nimitz and the new Ford classes have bulbous bows to delay the bow wave riding up and slowing them down. Earlier carriers didn't have them, because length-to-beam and installed engine power alone was sufficient with their more slender hull forms and reduced draft.

In general, the more sophisticated a material is, or the more extreme the performance requirements become, the tighter the process control involved in manufacture, maintenance, and the more lengthy the list of caveats regarding appropriate uses and problems to be aware of. That said, there are ideal applications for all of these materials. These new HEAs are showing great promise for our next generation engine components to make more power while minimizing weight, thus improving overall efficiency of energy usage.

#10 Re: Science, Technology, and Astronomy » Why the Green Energy Transition Won’t Happen » 2024-04-22 21:01:13

Calliban,

I read the article. It's not telling you or I anything we don't already know. Electricity is not some magical way to cheat basic physics.

I noticed that they referenced low and high entropy energy machines. There's a reason I keeping calling photovoltaics, wind turbines, and electrochemical batteries "entropy machines". They require an inordinate entropy change to take highly disordered matter, by using enormous amounts of energy input to transform them into highly ordered matter. However superficially efficient they appear to the indoctrinated vs educated, they're factually the most highly ordered of all our machines, thus the most energy-intensive. Anything that requires inordinate quantities of polysilicon, composites, Lithium, and Copper to function at all, is definitionally energy-intensive. As of right now, almost none of that energy comes from other entropy machines, because entropy machines don't generate enough surplus energy to do that in an economical way. Unless almost all of the energy to make them and power them comes from CO2-free sources, and no matter how else indoctrinated or malevolent people try to obscure basic physics, they are in fact using more input energy to create and operate them. That is why they cost so much. Almost all of the money sunk into them represents money paid for energy to make and operate them, not repairing or recycling them, since that is almost impossible. Worse still, recycling them requires more energy than making a new entropy machine from scratch.

These entropy machines represent an energy treadmill. They're a losing proposition if we zoom out far enough to stop fixating on the end result and start focusing on all the inputs required. If you're going to predominantly use low energy density intermittent energy sources, then you need low embodied energy materials to construct machines that last a very long time, or eventually you run out of energy to sustain your way of life. The implications are that stark and the results won't be pretty.

There's no magic or "wonderment" in this for people who don't have emotional or ideological investment into what the end result looks like. It looks really bad from my perspective, because from an input energy and ecology standpoint, it is bad. While I wish that wasn't the case, I can't flippantly ignore reality and hope that it changes to suit my beliefs about how it should work. Maybe new inventions will come along to fix not-so-green energy's numerous and varied problems, but that's hoping for something that doesn't presently exist. Hoping for change is not a valid engineering strategy for winning this energy and ecology battle.

That's why I spent so much time and effort explaining this so many different ways, whilst repeating things I thought shouldn't require so much repetition, but it looks like it's mostly fallen on deaf ears. I want people to know why this strategy will fail before it finally does fail. It's my hope, though perhaps a vain one at this point, if people who have more than a passing interest in science and technology truly cannot understand it, so that the same mistakes aren't repeated during the next incarnation of whatever follows.

You and I have both spent lots of time pointing out various more practical ways forward for these green energy concepts, that at least have some chance of working to the degree and at the scale required. Perhaps some bright young person, much smarter than I'll ever be, will pick up what we're laying down, use what they know that we don't, and solve these problems in ways we never thought of. That is my only desire. I recognize that we have some significant and serious long-term issue with anthropogenic global warming, maybe more of one than we know, and that the problem requires real solutions that can be implemented in the hear and now, rather than some far off point in the future. We'll only start to appreciate the unique nature and depth of the problem after we recognize the scope and scale of trying to replace hydrocarbon energy with anything else. Our present dependence on it is starting to become a little scary. We need realistic alternatives, but thus far there's no serious effort to pursue them.

Enough people will independently figure this out in their own way, sooner or later. I just hope there's enough time left to pursue actual solutions after we're done mucking around with these non-solutions.

#11 Re: Terraformation » Para Terra formation in Orbit, with orbital services. » 2024-04-22 16:27:13

Chinese scientists recently reported a de novo route for artificial starch synthesis from carbon dioxide (CO2) for the first time. Relevant results were published in Science on Sept. 24.

The new route makes it possible to shift the mode of starch production from traditional agricultural planting to industrial manufacturing, and opens up a new technical route for synthesizing complex molecules from CO2.

Starch is the major component of grain as well as an important industrial raw material. At present, it is mainly produced by crops such as maize by fixing CO2 through photosynthesis. This process involves about 60 biochemical reactions as well as complex physiological regulation. The theoretical energy conversion efficiency of this process is only about 2%.

Strategies for the sustainable supply of starch and use of CO2 are urgently needed to overcome major challenges of mankind, such as the food crisis and climate change. Designing novel routes other than plant photosynthesis for converting CO2 to starch is an important and innovative S&T mission and will be a significant disruptive technology in today’s world.

To address this issue, scientists at the Tianjin Institute of Industrial Biotechnology (TIB) of the Chinese Academy of Sciences (CAS) designed a chemoenzymatic system as well as an artificial starch anabolic route consisting of only 11 core reactions to convert CO2 into starch.

This route was established by a "building block" strategy, in which the researchers integrated chemical and biological catalytic modules to utilize high-density energy and high-concentration CO2 in a biotechnologically innovative way.

The researchers systematically optimized this hybrid system using spatial and temporal segregation by addressing issues such as substrate competition, product inhibition, and thermodynamical adaptation.

The artificial route can produce starch from CO2 with an efficiency 8.5-fold higher than starch biosynthesis in maize, suggesting a big step towards going beyond nature. It provides a new scientific basis for creating biological systems with unprecedented functions.

"According to the current technical parameters, the annual production of starch in a one-cubic-meter bioreactor theoretically equates with the starch annual yield from growing 1/3 hectare of maize without considering the energy input," said CAI Tao, lead author of the study.

This work would open a window for industrial manufacturing of starch from CO2.

"If the overall cost of the process can be reduced to a level economically comparable with agricultural planting in the future, it is expected to save more than 90% of cultivated land and freshwater resources," said MA Yanhe, corresponding author of the study.

In addition, it would also help to avoid the negative environmental impact of using pesticides and fertilizers, improve human food security, facilitate a carbon-neutral bioeconomy, and eventually promote the formation of a sustainable bio-based society.

TIB has focused on artificial starch biosynthesis and CO2 utilization since 2015. To carry out such demand-oriented S&T research, all kinds of resources for innovation have been gathered together and the integration of "discipline, task and platform" has been strengthened to achieve efficient coordination of research efforts.

This study was supported by the Key Research Program of CAS and the Tianjin Synthetic Biotechnology Innovation Capacity Improvement Project.

Journal: Science

Article Title: Cell-free chemoenzymatic starch synthesis from carbon dioxide

Link: http://dx.doi.org/10.1126/science.abh4049

Article Publication Date: 23-Sep-2021

#12 Re: Science, Technology, and Astronomy » Hydrogen Fuel Cell Vehicles » 2024-04-20 14:03:41

tahanson43206,

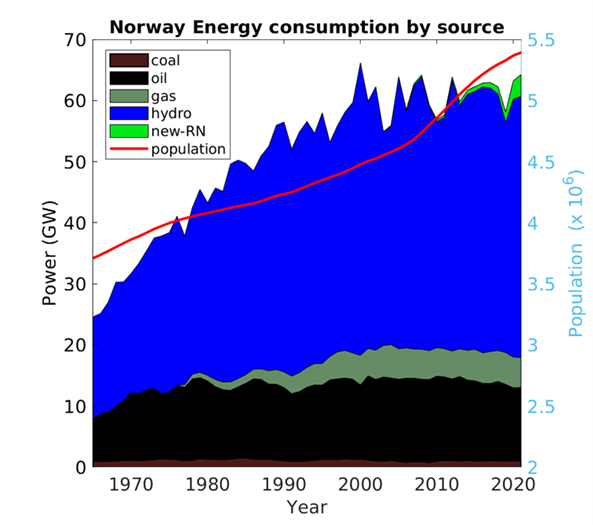

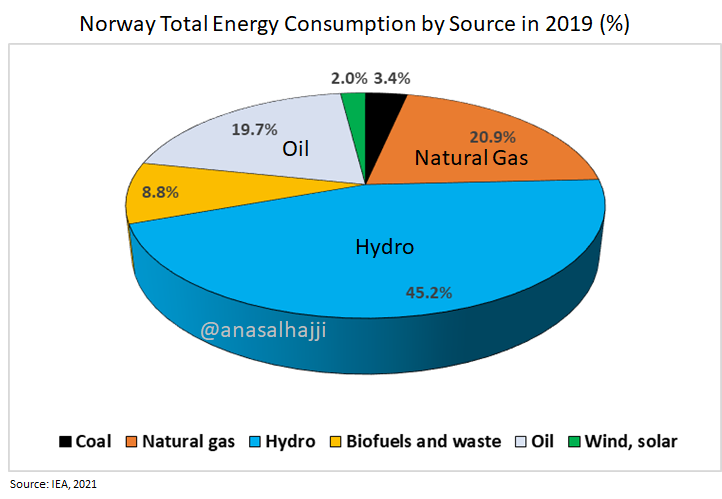

According to Google, Norway secured 98% of it's energy from a combination of hydropower and wind.

Norway's "energy", according to the graphs I posted, which I also found using Google, is 45% hydro, perhaps 5% wind turbines and photovoltaics by now, and 50% oil, gas, and coal.

Norway's "electricity", which is merely one form of "energy", is only half of their actual energy consumption.

If we're going to talk about "electricity" vs "energy", then let's use appropriate labels.

Norway is exporting their oil and gas to the rest of Europe. Their government is then using the profits from oil and gas sales to fund their "green energy" projects.

It really doesn't matter what kind of shell games or word games we attempt to play with our "energy" consumption. By definition, a global problem doesn't "go away" because you exported the source of the CO2 emissions elsewhere.

Norway's 2021 "Energy" Consumption by Source, according to the EIA

Coal - 3.1% / 27,996TJ

Oil - 36.1% / 327,565TJ

Natural Gas - 3.8% / 34,951TJ

Heating - 2.6% / 23,367TJ

Biofuels and Waste Burning - 6.9% / 67,729TJ

Electricity - 47.5% / 431,967TJ

446,657TJ (124,071GWh / 124,071,385,414,890Wh) - Norway's burning of something other than Hydrogen, for "energy"

3,722,178,784kg / 3,722,179t of Hydrogen required to replace coal / oil / gas, at 33,333Wh/kg

They're creating capacity to generate 40,000t of "green Hydrogen", whatever that is, per year.

Norway requires 93 more plants of the same size to replace all that coal, oil, and gas they're presently consuming to create "energy".

154,470,419,536,000Wh <- That is how many Watt-hours of "electricity" Hysata's 95%+ efficient reverse fuel cell requires to replace Norway's coal, oil, and gas consumption, which is most definitely part of their "energy" consumption.

119,990,833,299,736Wh <- That is how many Watt-hours of "electricity" Norway produced from all "energy" sources, green or otherwise.

What is the main source of income in Norway?

The oil and gas industries play a dominant role in the Norwegian economy, providing a source of finance for the Norwegian welfare state through direct ownership of oil fields, dividends from its shares in Equinor, and licensure fees and taxes.

Cost of living - Norway is among the most expensive countries in the world, as reflected in the Big Mac Index and other indices. Historically, transportation costs and barriers to free trade had caused the disparity, but in recent years, Norwegian policy in labor relations, taxation, and other areas have contributed significantly.

#13 Re: Science, Technology, and Astronomy » Hydrogen Fuel Cell Vehicles » 2024-04-19 23:01:02

Well,

At least we know how Norway financed all of their green energy:

Norway expects to earn record $131 bln from oil and gas in 2023

Maybe Google thinks electricity is the only kind of energy consumed by Norway. People who are less ideologically motivated, or slightly more inquisitive, know otherwise.

The government’s total net cash flow from the petroleum industry is estimated to be NOK 986 billion in 2023 and NOK 832 billion in 2024. The estimate for 2023 is NOK 299 billion lower compared to the net cash flow in 2022.

Green is indeed the color of money, but not energy. Hydrogen has no color at all.

#14 Re: Science, Technology, and Astronomy » Why the Green Energy Transition Won’t Happen » 2024-04-19 20:06:51

SpaceNut,

I'm not sure what you're trying to point out here.

You can purchase a PT-6A engine right now from Pratt & Whitney if you have the money. It's an off the shelf item by that definition. If you think you can bolt it onto any existing plane and go flying, then you're mistaken. The mere fact that you can lay down cash and walk out with a product means very little. There's clearly a lot of engineering work that goes into making sure that the plane in question can use said engine, as-installed. Merely being able to purchase a PT-6A tells me very little about the suitability of the engine for the plane it's bolted to, nor what a plane with that engine installed might be able to do.

#15 Re: Science, Technology, and Astronomy » Why the Green Energy Transition Won’t Happen » 2024-04-19 18:26:59

SpaceNut,

Every power generating system is an engineered solution. You can buy a photovoltaic panel or wind turbine, but you can't buy an "off the shelf" photovoltaic or wind turbine farm, because no such animal exists. Every site is unique. The requirement for steel and concrete will be unique to the firmness of the ground that equipment is mounted on. You decide whether or not you want power, you pay money to an engineering firm, and then they figure out what parts they can buy or design and fabricate themselves.

You know what part of an electric power grid is a bespoke solution?

All the step-up and step-down power transformers fit that description. I'm not talking about the ones you see on power lines, I'm talking about the ones you see at step-up or step-down stations, as well as the power inverters if on-panel inverters are not used. When you pay for a photovoltaic farm, the people purchasing the power pay for all the non-standard equipment unique to the massive power fluctuations produced by photovoltaics and wind turbines, so that power surges and drops don't crash the entire grid. All that equipment costs real money, none of it is an off the shelf solution, and all of it must be paid by the consumer for the privilege of having unreliable intermittent energy on the grid, because a reliable grid doesn't require such equipment. This is engineering reality vs glossy sales brochure fantasy.

These thermal engineering solutions are going to start providing more than just power. They're going to collect and supply CO2, Argon, Xenon, Neon, Krypton, Sulfur, and other saleable industrial products so that those products don't have to be produced from scratch by burning something like natural gas or coal, solely to obtain that industrial product. Neon is required to make microchips. Argon is required for welding. Sulfur is required to make Sulfuric acid. The multiple revenue streams mean that the electric power consumer doesn't have to pay for the full cost of the plant, and consumers of the industrial products don't have to pay for specialty plants that burn fuel just to produce something that would otherwise be a natural byproduct of burning fuel.

#16 Re: Science, Technology, and Astronomy » Why the Green Energy Transition Won’t Happen » 2024-04-19 14:59:12

Calliban,

They're building a commercial electric power plant in Odessa, Texas.

NET Power has five other projects in the works, including two 280-MW plants in the U.S. that are being co-developed with Cayote Energy in Colorado and with Broadwing Energy in Illinois, as well as a 300-MW project in the U.K. with Whitetail Energy. Others are planned with Frog Lake Energy in Canada and with Wilhelmshaven Green Energy in Germany.

Once you prove that a gas turbine technology works, we have people in America, China, Europe, India, and Russia, who all know how to make the parts and implement the technology.

NREL / NETL / US DoE and various other national labs sunk a considerable chunk of money into basic development and testing of the gas turbine, supersonic CO2 compressors, and the high temperature diffusion bonded printed circuit heat exchangers, which the UK provided the expertise and hardware for. Those heat exchangers are approximately 1/8th the size and weight of more conventional tube-based heat exchangers.

Allison, Baker Hughes, Barber-Nichols, General Electric, Saudi Aramco, Toshiba, and a bunch of other players in the energy industry invested serious money and engineering expertise (all told, over a billion dollars, so about equal to the US government's contribution) into the project at various stages, and now we get to reap the rewards of that tightly focused investment into a technology that we know, beyond any shadow of a doubt, actually works. If it didn't work, or was thought to be a marginal improvement, or questionable value proposition, then we wouldn't have pilot plants and full scale commercial electric power generation facilities, based upon Brayton cycle sCO2 gas turbines, popping up around the US, Canada, Europe, and now China, India, and the Middle East.

sCO2 and supersonic CO2 compressors (referred to as "rampressors" or "RamGen" by Ingersoll-Rand), are the latest applications of well-established gas turbine engine technology. In the coming decade, sCO2 and RamGen will become cornerstone technologies for reliable green energy technology, transport, and industry. We're still in the early days of deploying this technology, but it will have profound implications, because it is significantly better than what it replaces in ways that matter. Rather than throwing our hands up in the air or pretending that there are no major issues with electronics-based energy technologies, we should continue pursuing technologies that can actually work at the scale we need them to work at, in order to make a meaningful difference.

#17 Re: Science, Technology, and Astronomy » Why the Green Energy Transition Won’t Happen » 2024-04-19 13:37:44

If you use Google just a little bit, you'll also find that Saudi Arabia and India have their own sCO2 pilot projects underway, and that the CSIRO was one of the initial investors into sCO2 technology.

#18 Re: Science, Technology, and Astronomy » Why the Green Energy Transition Won’t Happen » 2024-04-19 13:35:01

It looks like the Chinese are in the process of testing sCO2 gas turbines as well:

Shouhang and EDF to Test s-CO2 Cycle in Concentrated Solar Power

China could be the first to deploy s-CO2 in CSP

The world’s initial Concentrated SolarPower (CSP) plants continue to use the legacy steam cycles of conventional thermal plants. But steam cycle is a mature technology with temperature-based efficiency limits, hampering the potential to raise efficiency and lower costs. Consequently, international researchers have investigated a new power cycle, a closed loop supercritical carbon dioxide cycle (s-CO2).

Marking the first time s-CO2 cycle will be tested in an operating CSP plant, starting this month, the French utility company EDF will partner with Chinese CSP technology manufacturer Shouhang to convert a demonstration CSP plant built three years ago at the Gobi Desert solar park at Dunhuang from steam cycle to an s-CO2 power block.

“The way that people approach risk in China is different; I think they are more open for such innovation. They don’t trust so much the modeling work; so they build it. It’s quite sad that today it’s easier to do such projects in China than in a western country, but it makes working in China very exciting,” commented Yann Le-Moullec, EDF Chief Engineer in China R&D.

Le-Moullec, who announced the study-Retrofit of Dunhuang 10MW molten salt plant with a high temperature supercritical CO2 cycle at the Annual SolarPACES Conference 2018 in Morocco, is now working in China to implement the EDF collaboration with Shouhang, which built the 10MW plant to be used in the demonstration and was among the first to complete a 100MW tower CSP project in China’s first batch of demonstration projects.

After ten years in renewable energy R&D at EDF in France, then in China, Le-Moullec is now starting a two-year evaluation of its feasibility and the readiness of equipment suppliers in China and abroad. “With a lot of completely novel technology, suppliers might be eager to offer us some equipment, but the selection of which supplier we trust and how to qualify them, is our first issue at the moment,” he pointed out.

Why demo a not-yet-commercial power cycle so soon after commissioning steam cycle?

“Shouhang think s-CO2 could be commercially viable in three to four years perhaps, so they are moving very quickly to the “next” technology,” Le-Moullec explained. “They think that, if it could be profitable, it’s worth taking this risk.”

The s-CO2 cycle will be swapped for the steam cycle in the 10MW “display demonstrator” that Shouhang initially built at their own expense to demonstrate the heliostats, solar receiver and air-cooled condenser they manufacture. Chinese suppliers typically build such smaller showpiece plants for potential customers to demonstrate their products in action. “It’s quite competitive in China, if you don’t have a project to demonstrate that your product will work it is very hard to sell them,” Yann explained.

Nurturing policies to develop domestic CSP

The policy of the Chinese government is to build demonstration tower CSP projects full scale: 50MW or 100MW, as the most efficient way to de-bug the engineering problems in “first sample” projects. By limiting problem-solving to just the technical aspects, developers and engineers are able to focus on just the engineering fixes needed to deploy a new technology. China’s CSP pioneers are not required to negotiate land deals, attract the lowest financing, or offer lower prices than gas, PV or wind, as in the US, Australia and Chile.

Instead, demonstration projects are typically built in a dedicated solar park, on land set aside for solar development. The government sets a guaranteed payment for power delivered for 25 years; and land rights are part of the deal. Chinese policy follows Spain’s example, where its first CSP pioneers received a uniform Feed-inTariff (FiT). A guaranteed pay rate best supports first-of-a-kind technology and births a robust engineering and supply chain. As a result of that policy, Spanish firms still dominate the CSP industry.

Although the government hopes to build a domestic supply chain, foreign firms are not ruled out when certain specifications justify it, even sometimes at a higher price. For example, Shouhang’s steam turbine for the 100 MW plant is supplied by US-based GE due to the specific requirements of the CSP industry.

Shouhang plans commercial CSP with s-CO2 at 100 MW within 5 years

Over the next two years the test takes place. The advantage of reusing the same plant is that only the steam power cycle will need replacing, reducing test time and money. The disadvantage is that it means the test will be run – for most of the time – at a lower temperature than s-CO2 cycles could handle. However, the plan is to operate at the higher temperature for a brief period in order to test the dedicated equipment.

Like their 100MW plant, the 10MW demonstration model has 15 hours of molten salt (60% NaNO3-40% KNO3) thermal storage, with molten salt as heat transfer fluid, and it operates in a typical 290°C to 560°C range, using dry-cooling. But its tower height is just 135 meters, with a 7 meter high receiver at the top, and its solar field comprises just 1,525 heliostats.

“There are two pieces of equipment that can be quite tricky, One is the molten salt to s-CO2 heat exchanger. It’s at very high pressure, very high temperature, a lot of mechanical issues have to be solved,” Le-Moullec explained. “It’s very hard to decide which is the best option, and how it can work. No one has experience, so there is no proof of working design. The other is the compressor. We optimize the cycle design in order to have a simple compressor, because compressing CO2 from its critical point with high efficiency is very new.”

The operation of the system will be a challenge too. Because it is a Brayton cycle, there is no accumulation in the loop: you cannot buffer the CO2 as you do with water in a steam cycle. “Your CO2 has to run through the compressor and the compressor has to operate at their nominal speed driven by the turbine,” Le-Moullec explained. “We decided to select a recompression design and to adapt it for our small demo with small equipment, but it has never been done with such a layout.”

Once suppliers are selected and parts built, the demo should be online by the end of 2020. To meet this goal of commercial s-CO2 in a CSP plant within five years, they must solve these technical problems over the next two. Then, if it is successful, Le-Moullec says the target is to start deploying this technology commercially in less than four to five years.

#19 Re: Science, Technology, and Astronomy » Why the Green Energy Transition Won’t Happen » 2024-04-19 12:50:31

Oh look, it's not just here in Texas, this project is in Spain:

The wonderful thing about reality is that it's real.

Edit:

The EU funded H2020 SOLARSCO2OL project aims to demonstrate a 2 MW supercritical CO2 (sCO2) cycle with heat provided by molten salts in a relevant industrial operational environment at the premises of an existing solar complex in Spain, composed of a 50 MW Concentrating Solar Power (CSP) plant and a 6.1 MW dual-axis tracking PV plant. The new pilot plant will consist of a purposely designed molten-salt storage system including a molten salt electric heater, a storage tank, and the salt-to-sCO2 primary heater connected to the sCO2 cycle. In specific relation to the turbomachinery, the project aims to demonstrate the reliability and the technical performance of all key components present in a simple Brayton sCO2 cycle, including the balance of plant and control systems. Ultimately, the overarching goal of the project is to serve as a stepping-stone towards hybrid sCO2 based CSP and PV plants able to provide cost-efficient, flexible, modular, scalable, and dispatchable solar power. Besides the specific demonstration objectives, and related component development and verification, the project aims to investigate the techno-economic performance of advanced hybrid CSP-PV layouts combining electric heaters and sCO2 cycles at higher temperatures, as well as the social and environmental acceptability of the proposed solutions. The project started in October 2020 and will span for a period of 4 years, with three clear phases: design optimization (up to months 18-24); manufacturing, prototype tests, detailed engineering, procurement, and installation (up to month 36); and operational experience, analysis and conclusive recommendations during the last year. The anticipated budget for the project is 15.5 M€, and it has received a grant of 10M€ from the European Commission. The SOLARSCO2OL consortium is formed by 15 partners from industry and academia with complementary expertise in the fields of CSP and turbomachinery. In this paper, an overview of the project objectives, deliverables, and time plan is presented together with a condensed first-year summary including preliminary results from the conceptualization and design phases for the demonstration plant and its components.

#20 Re: Science, Technology, and Astronomy » Why the Green Energy Transition Won’t Happen » 2024-04-19 12:37:25

tahanson43206,

I don't have "wild enthusiasm" for much of anything. I do look for things that work well, or at least to the degree required, which are critical aspects of providing the things society wants or expects. On-demand energy is one of the things society wants and expects, so then I go looking for technologies that provide that in better ways than what we currently have or use. I'm not sure how or why you or others think real money hasn't already been devoted to developing sCO2 turbines, but your beliefs about this are also entirely irrelevant to plainly observable objective reality.

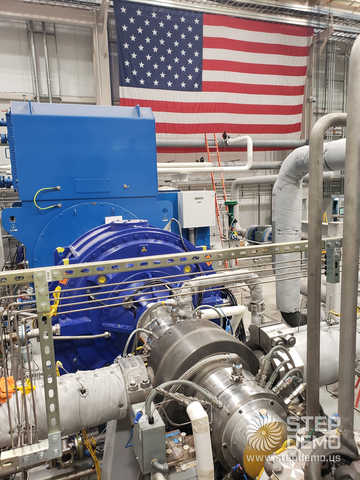

STEP Demo pilot plant makes new breakthrough for sCO2 power generation

The Supercritical Transformational Electric Power (STEP) Demo pilot plant, a $169 million, 10-megawatt supercritical carbon dioxide (sCO2) test facility at Southwest Research Institute (SwRI) in San Antonio, has achieved an industry first during commissioning by firing its natural gas heater and operating its turbine up to an intermediate speed of 18,000 rpm.

“Operating the integrated system is a noteworthy accomplishment. It follows the team’s successful component-based commissioning activities and demonstrates combined operation of all equipment, including plant controls, compressor, heat exchangers, heater, turbine and CO2 inventory in addition to the facility’s electrical and gas supply and cooling water systems,” said Dr. Tim Allison, director of SwRI’s Department of Machinery.

The STEP Demo project developed in collaboration with SwRI, GTI Energy, GE Vernova, the U.S. Department of Energy/National Energy Technology Laboratory (U.S. DOE/NETL), and several industry participants. The project’s central goal is to dramatically improve the efficiency, economics, operational flexibility, space requirements and environmental performance of this new technology. The STEP Demo pilot plant is one of the largest demonstration facilities in the world for sCO2 technology, and achieved mechanical completion in October 2023, when major subsystems were installed and began commissioning.

System commissioning tests will continue over the next several months to achieve maximum power in its current configuration by increasing operating temperatures to 500 °C and ramping up the full turbine speed of 27,000 rpm. The turbine was developed jointly by SwRI and GE Vernova Research Center and is being tested in a simple recuperated configuration of the plant. The plant will eventually operate at 715 °C to achieve full 10 MWe output.

“This is an important step for our sCO2 demonstration plant,” said SwRI Project Manager Dr. Jeff Moore. “The STEP Demo team is thrilled to have achieved this significant milestone of integrated plant operation.”

STEP Demo is a unique facility designed to demonstrate high-temperature sCO2 power generation, which increases efficiency by as much as 10% due to its favorable thermodynamic properties. Carbon dioxide is nontoxic and nonflammable and, when it is held above a critical temperature and pressure, it can act like a gas while having the density near that of a liquid. The sCO2 turbomachinery is approximately one-tenth the size of conventional power plant components, which shrinks the physical footprint and construction cost of any new facilities. Additionally, the sCO2 power cycles are compatible with many heat sources including concentrating solar power, industrial waste heat, geothermal power and advanced nuclear power plants.

“I am excited that our team is now starting to demonstrate supercritical CO2 technology that can have a positive impact on the planet by making clean energy more affordable and efficient, and decarbonizing more challenging industrial applications through waste heat recovery,” said Bill Follett, STEP Demo program director at GTI Energy.

SwRI is an industry leader in the development of sCO2 power cycles. Staff members have conducted numerous U.S. Department of Energy projects advancing the efficiency, reliability and commercial readiness of sCO2 power cycle turbomachinery, heat exchangers, cycles and systems. The team’s extensive experience with sCO2 technology is key to making the STEP Demo project a successful landmark demonstration.

For more information, visit https://www.swri.org/industry/advanced- … ilot-plant .

SwRI, GTI Energy, GE celebrate mechanical completion of $155 million supercritical CO2 pilot plant

Novel Gas Power Plant With No Air Emissions Set in Texas

Natural gas power plant developer NET Power LLC, with partners Baker Hughes, Occidental Petroleum and Constellation Energy, will narrow selection of an EPC contractor by year end to build an estimated $750-million to $950-milloin million utility scale power plant that it claims will be the world's first to burn natural gas with oxygen to generate power and produce pure carbon dioxide as a sellable byproduct with no harmful air emissions.

The project will be built in the Texas Permian Basin at an Occidental hosted site near Odessa.

A 50-MW pilot plant created to test the closed-loop supercritical technology—which was completed in La Porte, Texas near Houston by EPC contractor McDermott in 2021—successfully synchronized the power it produced to the Texas electric grid after operating for more than 1,500 hours.

When completed, the larger Odessa project will combust natural gas and capture an estimated 860,000 tonnes of CO2 per year, NET Power said “The technology can get energy out of natural gas with no emissions, no tailpipe, no stack,” firm CEO Ron DeGregorio told ENR. Pure oxygen reduces fuel consumption and increases flame temperatures, with no nitrogen oxides, sulfur oxides or carbon dioxide emitted to the air, he said.

The resulting CO2 is expanded in the turbine and moves into the heat exchanger where water is removed and remaining CO2 is either recaptured or compressed, pumped back into high pressure and reheated in the heat exchanger. The process produces “pipeline quality industrial CO2,” he said, which can be sequestered.

The plant does not have units to capture air emissions of CO2 and other harmful substances. Its only air emission is water, DeGregorio added.

The technology is clean, reliable, dispatchable and economical, according to the CEO. “It will be able to compete without subsidies on a levelized cost of electricity and will beat highly efficient combined-cycle plants with carbon capture at the end of the pipe,” he said.

NET Power’s technology was ranked by the Massachusetts Institute of Technology in 2018 as one of its 10 breakthrough technologies.

“The plant puts the carbon dioxide released from burning natural gas under high pressure and heat, using the resulting supercritical CO2 as the ‘working fluid’ that drives a specially built turbine. “Much of the CO2 can be continuously recycled; the rest can be captured cheaply,” said MIT Technology Review. “Of all the clean-energy technologies in development, NET Power’s is one of the furthest along to promise more than a marginal advance in cutting carbon emissions.”

Multiple Revenue Streams

The utility-scale project to be built will generate 370 MW of power, with 300 MW going to the grid and 70 MW used to run the plant’s air separator unit. The technology burns pure oxygen, which requires the separation of air. “The cost is figured into the economics,” DeGregorio said.

The plant will have multiple revenue streams related to its power generated as well as to the CO2, nitrogen and argon byproducts produced.

Pre-front end engineering and design is complete, with final engineering expected to begin in early 2023, after the EPC contractor is selected, DeGregorio said.

There are five shortlisted construction contenders for the project that he declined to name. They will be narrowed to two before a final selection is made.

The contractor will update the cost estimate and design the project in a way to make it more modular, DeGregorio said. Construction is set to begin in 2024 and finish in 2026.

NET Power has five other projects in the works, including two 280-MW plants in the U.S. that are being co-developed with Cayote Energy in Colorado and with Broadwing Energy in Illinois, as well as a 300-MW project in the U.K. with Whitetail Energy. Others are planned with Frog Lake Energy in Canada and with Wilhelmshaven Green Energy in Germany.

The developer also is working with other large utilities that have shown interest in building plants, DeGregorio said, as well as with multiple energy investment funds. “We have a lot going on,” said the executive, who added that NET Power also licenses its technology.

Energy technology company Baker Hughes joined the Permian Basin group in January and is developing the facility’s supercritical CO2 turboexpanders and other pumping and compression technology and will provide equipment for other projects.

The pilot plant was built with Toshiba equipment but Baker Hughes will supply it for the scaled-up project.

DeGregorio said NET Power has been quietly developing the technology for 12 years until completion of the demonstration plant. The original idea for the technology came from scientists at low-carbon energy developer 8 Rivers, which worked with air separators and is an early investor in NET Power.

Early investors also include Constellation. Occidental joined in 2014 and now is its largest investor. McDermott was previously an investor.

Occidental said Nov. 9 that its third-quarter profit rose to $2.5 billion in the three-month period ended Sept. 30, compared to $628 million during the same time last year—with the firm citing higher gas and oil prices due to the Ukraine war. Revenue increased nearly 40% to $19.5 billion, the firm said, compared to $6.8 billion in the same 2021 period.

The energy firm also noted a continued focus on carbon capture, eyeing development of up to 30 direct air capture plants in Kleberg County, 'texas, in an area it said has access to underground geologic reservoirs that could store captured carbon.

NETPower said it intends to pursue government support, including loans and incentives under the 2021 federal infrastructure law and carbon capture tax credits in the new Inflation Reduction Act.

All the people who need to be convinced, and those would be the people who have invested their money, have already been convinced.

The Odessa Supercritical CO2 Power Plant is coming online in 2026.

Continue your disbelief, or don't. I really don't care. It has no bearing on reality. This is happening right now. All those pictures you see of the facilities from the links I provided were built here in Texas (San Antonio, La Porte, Odessa is still under construction). They're not internet hoaxes. You can see overhead Google imagery of them. No belief in what I write is required.

#21 Re: Science, Technology, and Astronomy » Why the Green Energy Transition Won’t Happen » 2024-04-19 12:05:20

Two frequently overlooked aspects of a successful vs failed energy transition are the national security implications and societal cohesion.

Firstly, the very idea that you can talk your way out of any fight, or somehow avoid all conflict, if only you acted in some specific way, is flat out wrong and false at every conceivable level and in every possible way, period. By no means should you actively seek out any conflict, but neither should you be so naive as to believe that conflict won't actively seek you out, even though you were never interested in fighting with anyone.

The defense industrial base of every allied nation has certain defense spending obligations it's required to meet.

1. Every nation which wishes to remain sovereign and independent must maintain a professional standing army led by a core of educated officers (bachelor of science for lower ranks, master of science of doctorate for higher ranks) who will manage and direct military operations, when the need arises.

2. Every nation must have a supply of arms and munitions to supply to their troops. This takes the form of small arms to equip individual soldiers, mortars and artillery for fire support, armored personnel carriers to transport soldiers and their equipment around the battlefield, and main battle tanks that provide direct fire support. More recently, in lieu of a professional air force, drones are a new requirement for battlefield recon, scouting, and light attack roles traditionally filled by much more expensive aviation assets. Helicopters and fixed wing cargo transports are nice to have, but they may not be usable on a modern battlefield without well-established air supremacy.

3. A professional air force and navy are very expensive to maintain to the degree required to make them survivable in combat, but the roles such assets fill are still important, so patrol and transport vessels and surveillance aircraft, manned or unmanned, are minimally required when the nation in question has ocean front property.

Anything beyond that is highly desirable to have available if your nation can afford it and your leadership decides it's important to have available to keep the peace, but those listed capabilities are integral to any competent fighting force seeking to present a credible threat of resistance to any would-be aggressor state.

Every aspect of those listed capabilities are incredibly energy and resource intensive. They require steel, Titanium and other light alloys to reduce the weight of certain parts, Copper, Lead, plastics and rubber, diesel fuel, production of complex motorized vehicles and the machinery used to create them, weapon systems such as small and large caliber cannons, explosives, computers, radar and infrared sensors, as well as various other electronics such as radios and night vision devices. Some defense items your nation may be able to easily procure from allied nations for a fair price, but others really must be made at home. Unfortunately, those home-built items typically represent the lion's share of input energy and maerials, because they involve manufacture of crew served weapons, vehicles, munitions, small arms, armor, uniforms, and software development to operate nationally customized drones and sensor systems to create a "big picture" of the battlefield conditions your military is facing. You will receive aid from your allies, but that aid may not be timely, or it may be insufficient.

Ukraine desperately needs artillery shells and howitzers, for example. 155mm artillery is NATO standard, even though other calibers such as 105mm light howitzers are still used. A factory that makes artillery shells in volumes relevant to a shooting war is not a small facility, and it continuously consumes energy like it's going out of style. As we see in the case of Ukraine, there's no pragmatic way to outsource this capability, either. Artillery shells and propellant charges are very heavy and expensive to produce and transport. Modern explosives are not sensitive at all to rough handling, thankfully, yet they are also the most energy intensive part of the entire process of making an artillery shell. You need a chemical factory and you need highly skilled operators who know enough to not get themselves killed, which implies a high level of education and training. That requires teachers, relationships, communication skills, knowledge transfer materials from ABCs to "don't mix Chemical A with Chemical B unless you want to get blown into the middle of next week", computers, abundant food, clean water, sanitation, and the list goes on. Law and order are quite important as well. All of this stuff is interconnected, and you cannot reasonably obtain one item from the list that you really want, without also obtaining all the others.

You, personally, may not want to spend any of your national treasure or energy on these costly defense items and services, but they will always be an important aspect of assuring that you and your children will have a worthwhile future to look forward to, even as they threaten to take it away. The fundamental point behind this, is that national defense requires a lot of energy, which undergirds all other aspects of a thriving human society. As such, your foundational energy supply needs to be highly reliable, durable, long-lived, not subject to the capricious nature of the local weather, and secure against attack. Thermal power systems check off all of those boxes.

Secondly, the very idea that you can expect to receive all the "goodies" of a high-functioning civil society, without an equal willingness to pay the price required to maintain such a state of affairs, is another blatant falsehood. The price to be paid is cheap / abundant / secure energy, abundant food and fresh water supplies, a local industrial base capable of supplying most of your civil and military needs, and a national culture that values your own people above all others. Societal cohesion demands that almost everyone buys into the national logos and mythos.

When people are not worried about where their next gallon of gas or kilowatt-hour of electricity is coming from to get to work and feed their children, society will thrive. Conflict never goes away entirely, because jealousy is an incurable human emotion that is part of the human condition, but you will rarely see people in affluent neighborhoods busting down the doors of their neighbors to take what they have. When you have an education, a job that can pay your bills, a car to take you where you need to go, a roof over your head, food and drink for your family, a little entertainment here or there, and a future retirement to look forward to, most reasonable people would not risk all of that to go take something from someone else. That is why we have civilized societies. A well-functioning society basically squashes the perceived need to do any of that, and instead rewards greater cooperation. When you don't have those things, and cannot see a path forward to obtain them, that is when real conflict begins, and that can get very ugly, very fast.

That is the "how and why" energy matters so much to the security of a nation and its citizenry.

#22 Re: Science, Technology, and Astronomy » Why the Green Energy Transition Won’t Happen » 2024-04-19 10:30:43

tahanson43206,

sCO2 technology was developed, specifically because it was more competitive than steam or existing gas turbine engine technology. There is no such thing as a 50% efficient 10MWe conventional gas turbine, let alone a 50% efficient 250kWe conventional gas turbine. There is most definitely no such thing as a 300MWe steam turbine the size of an office desk.

sCO2 has the backing of NREL (National Renewable Energy Laboratory), NETL (National Energy Technology Laboratory), US DoE, SWRI (SouthWest Research Institute), General Electric, Toshiba, Barber-Nichols (the people who gave us the RS-25 turbopumps, amongst other things), Ingersoll-Rand (the people who gave us supersonic inlet velocity CO2 compressors that reduce the size of coal power plant CO2 scrubbers from a house to a 20ft transport container), Allison (the people who make the transmission gearboxes for large trucks, as well as gas turbine engines), and a number of universities around the country, and in Europe. The renewable energy people are mostly oblivious to this because they think absolutely everything is about electricity and its magical efficiency.